The Re-Impact Technology

Re-Impact blades offer a number of unique advantages – first and foremost the highest possible degree of ball-control and ‘touch’.

The blades are built similar to how musical instruments are manufactured, and one can hear and feel what is harmonically transferred when contact is made with the ball.

Even OFF blades offer a blend of both attack and defense which will work for all systems of play. This section will attempt to describe some of the technologies that go into the Re-Impact blades, and explain why they are truly unique.

1. Extra catapult with enhanced feel and control

Re-Impact blades generally change the properties of rubbers attached to them as if they were speed-glued. Special physical properties of the assembled wooden plies are amplified as a result of the

- configuration of the plies,

- tuning of the plies,

- specially selected materials,

- singular asymmetrical shape of the blade,

- unique design of the grip,

- special glue (to glue plies together) that does not interfere with the wood properties,

- number of other patented inventions.

This allows vibrations of one ply to be superimposed onto those of the others, resulting in increased inner dynamics of the wood, as well as enhanced feel and control.

Interfering vibrations due to the swinging of the blade are dampened in Re-Impact blades, so you will only feel the vibrations produced by the impact and the spin of the ball.

2. More spin with the right rubbers

The blades also offer a larger potential for producing spin compared to conventional products. This results from a complex interaction of the inner and outer plies – their acoustic vibrations are amplified, and transferred to the rubber, producing a solid increase in spin production.

It is very important to choose rubbers which will harmonize with the respective models, or the properties of the blade and the properties of the rubber might either nullify each other or, added to one another, resulting in too much amplification and hence reduced control.

When choosing inverted rubbers for your Re-Impact blade, it is recommended to choose a sponge thickness one step lower than normal (e.g. 1.8mm instead of 2.0mm). This is because the extra catapult that most Re-Impact blade offer, enhances the effect of the sponge. The thinner sponge will add further control, so this is an additional benefit.

3. Ultra light weight and much less stress on joints

The singular asymmetrical shape of Re-Impact blades deminishes the air-resistance of the blade, making it far more easy to handle than other blades. Their shape and their special light weight are part of the fundamental design of these blades which intends to unburden the joints of a player’s arm and shoulder.

As a special consequence these blades are particularly well suited to players who suffer from limited mobility or reduced muscle strength. The technology also offers great value to players who are no longer as quick on their feet, or as powerful with their shots, and who need more subtle tactics and technique to continue to compete at the same level.

4. Large Sweetspot

Manufacturers often add carbon or other composites to their blades to enlarge the ‘sweetspot’. Nearly all Re-Impact blades have an enlarged sweet-spot similar to carbon-blades; however, they are made of 100% wood, so that the control and dwell time that wood offers is maintained.

Re-Impact blades are designed for competition and fully comply with International guidelines for blades, ie. all blades are completely legal under the international rules of the ITTF.

5. The KSLS system, and multiple levels of play

An added unique quality the majority of Re-Impact blades have is that they will allow two different levels of play. On each of those two levels the properties of the wood will work in different ways. The levels are activated by twiddling the blade.

This is how it works. A table-tennis ball will always hit a blade at an angle. Wood is less elastic when impacted in the direction of its fibers than when impacted at an angle with the fibers. In Re-Impact blades the fibers of the core-ply run at an angle with respect to the fibers of the outer plies. This is part of the so-called “KSLS system”, which has been developed to reflect the audible and tangible vibrations in the blades. In the first level of play the ball’s impact will be reflected in such a way that the blade will respond and resound with its highest degree of elasticity; in the second level of play it will respond and resound with its lowest degree of elasticity.

The KSLS System visibly indicates these two levels (or positions) by the grooves which are cut in only one side of the grip (pictured below).

Groves visible on only one side of the handle

If you have a blade for a right-handed player in front of you, grip towards you, forehand facing upwards, the grooves are in the right-hand side of the grip. The core’s fibers now run diagonally from the upper right-hand side to the lower left-hand side; completely identical in forehand and backhand. As the KSLS system reflects the waves against the direction of the fibers, vibration inside the blade increases, which will greatly increase the ball-feeling but decrease the speed

If you twiddle the blade 180 degrees, bringing the backhand side face up, then the grooves are on the left-hand side of the grip. The core’s fibers now run exactly the other way, that is, from the upper left-hand side to the lower right-hand side. The vibrations caused by the impact of the ball will now run with the direction of the fibers, which will result in less vibration, less ball-feeling, and more speed.

Balsa wood is known to absorb instead of reflect vibrations. Therefore, in the plies used for the balsa wood Re-Impact blades, very small channels for transport are created, in order to transfer the vibrations resulting from the impact of the ball in a very short time to the nerves that feel them in the player’s hand. These small transporting channels must not be wider than 0.25 mm, as this is the smallest seam ITTF rules allow for gluing woods.

The smallest cutting blades are used for making these channels. In contrast to what happens when sawing the wood (as commonly done by blade manufacturers), cutting with these blades doesn’t damage the fibers of the balsa. The fine grooves which are cut out, always going with the grain, are filled fully up when the plies are glued together. The resulting channels for transport are less than 0.1 mm wide. In Re-Impact balsa blades, cuts 10mm apart are made in every ply, so the ball will always make contact with at least two channels which quickly transport the bundled information to the hand, being enhanced at certain points on the way due to the asymmetric outside and the KSLS system.

The smallest cutting blades are used for making these channels. In contrast to what happens when sawing the wood (as commonly done by blade manufacturers), cutting with these blades doesn’t damage the fibers of the balsa. The fine grooves which are cut out, always going with the grain, are filled fully up when the plies are glued together. The resulting channels for transport are less than 0.1 mm wide. In Re-Impact balsa blades, cuts 10mm apart are made in every ply, so the ball will always make contact with at least two channels which quickly transport the bundled information to the hand, being enhanced at certain points on the way due to the asymmetric outside and the KSLS system.

The KSLS System

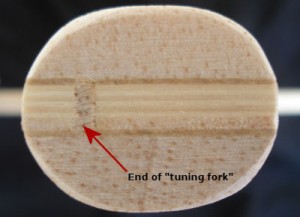

The KSLS system guides, step-wise, the vibration caused by the ball’s rotation down into the grip. It is similar to a tuning fork and works like a diaphragm in the throat of the blade, providing feedback of the ball’s spin to the hand holding the blade.

With combination-blades the two levels of play are not indicated; but they are there and provide further options for disrupting activity using the different characteristics of the outer plies.

6. More about Balsa Wood

Balsa wood is used in many of the Re-Impact blades, which contributes to the very low weight of their blades, but it also takes advantage of some of the unique properties of balsa (described below), which is not found in most other woods. There are more than 50 types of balsa woods, all exhibiting subtle but significant variations in characteristics. Re-Impact consistently selects special varieties of balsa for its special purposes; this in order to optimize the blades’ properties, and this also ensures consistency among their blades range.

Other wood-types will impart speed to a ball in a more or less one to one ratio to the force used (or the speed coming in), but not balsa. If force or impact is below a certain level, balsa’s catapult will be lower than the catapult of most other woods – much lower if the force or impact is small, less so if greater.

However if the force or impact is above this level, the balsa’s catapult will be more than that of the average wood, initially a bit more, but increasingly more if the force or impact are increasing. So, when play is slow, the balsa is extremely slow, but when play is speeding up, the balsa will speed up even more, which is illustrated below:

The general qualities of balsa are enhanced in a special way in Re-Impact blades. As a result, the vibration inside the body of the blade originating from the ball’s impact and spin, causes – due to static charging – air to flow around in the spongy structure of the balsa wood. Heat is generated (up to 6 degrees Centigrade) which compresses the already condensed air further and thus results in an increased catapult effect on offensive strokes. However, the surfaces of the plies in the blade are specially treated to compensate for this effect on defensive strokes.

The change in catapult also means that the throw of a balsa blade changes with the speed. Balsa is relatively low throw, but when things speed up and catapult is increasing, dwell time will decrease and throw will be even lower. This is one of the properties that make balsa so suitable for blocking (particularly with pimples), as when you block a loop softly (loose grip), the balsa has a high braking effect, allowing you to take the pace off the ball very effectively. When blocking solidly, or against very fast loops, the low dwell time and throw, means the bat will be much less affected by spin, and produce a low ball, making it harder for the opponent to attack.